In the modern building materials system, construction-grade HPS ( hydroxypropyl starch ether) is widely used as a high-performance additive in products such as dry-mixed mortar, putty powder, tile adhesive, and self-leveling mortar. HPS is made from natural starch through etherification, modification and optimization treatment, and it is both environmentally friendly and highly efficient. It plays a significant role in improving construction performance, regulating rheological properties, enhancing water retention and extending open time, and is an indispensable functional additive in modern building material formulations.

The main characteristics of construction-grade HPS

1.1. Excellent rheological regulation performance

HPS has a unique molecular structure. Its long-chain hydroxypropyl groups can form a stable spatial network structure in the system, which regulates the fluidity and thixotropy of the mortar system. Under stirring conditions, the system has good fluidity. After coming to a standstill, it forms a certain structural strength, thereby preventing the material from sagging or slipping.

1.2. Excellent water retention and anti-segregation properties

Construction-grade HPS can effectively absorb moisture and form a uniform water film layer inside the mortar, thereby significantly enhancing the water retention of the material. This feature is particularly crucial for cement mortar and gypsum-based products, as it can prevent powdering, cracking and poor bonding caused by rapid water loss during construction.

1.3. Excellent thickening and stabilizing effects

By working in synergy with cellulose ethers (such as HPMC and HEMC), HPS can further enhance the thickening effect of the system and improve the smoothness of the application during construction. Meanwhile, it plays a stabilizing role in the dispersion of pigments and fillers in the formula, making the mortar system more uniform and stable.

1.4. Outstanding environmental protection and safety

HPS is derived from natural plant starch, which is non-toxic, harmless and biodegradable, fully in line with the development direction of green building materials. In practical use, it will not release harmful gases or pose a health threat to construction workers.

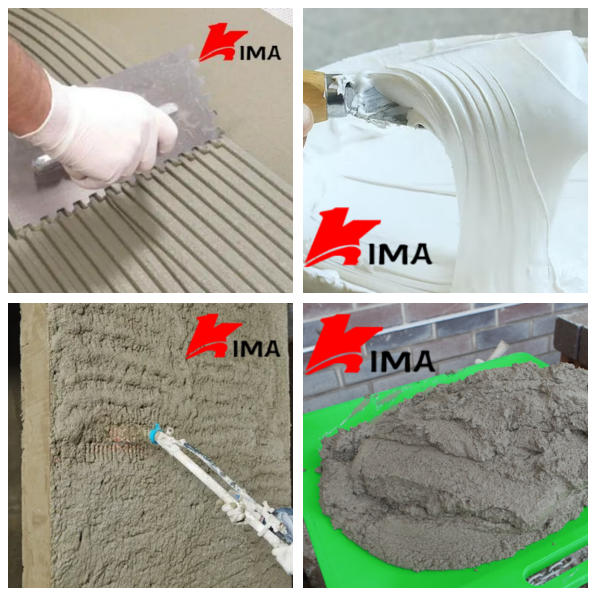

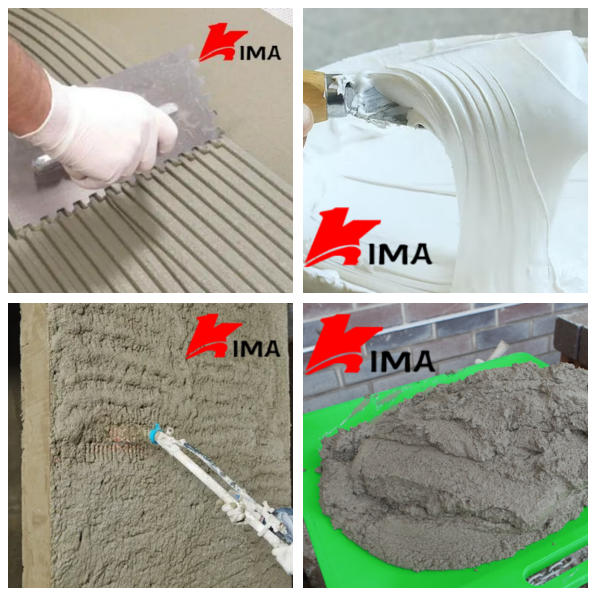

The application effect of HPS in building materials

2.1. Application in Putty Powder

In the formula of interior and exterior wall putty, HPS can significantly improve the construction performance. Its water-retaining effect can prevent the base layer from absorbing water too quickly and avoid cracking of the putty. Its rheological regulation performance makes the coating process smoother and the film formation more uniform, enhancing the flatness and smoothness of the finished product surface.

2.2. Application in Tile Adhesive

Tile adhesive requires excellent thixotropy and anti-slip performance. The addition of HPS can keep the tile adhesive in good fluidity during stirring, and quickly form a "pseudoplastic" structure in the construction state, enhancing the initial adhesion and anti-slip performance of the tiles, while extending the working time and improving the construction efficiency.

2.3. Application in Mortar and Self-leveling

In floor mortar and self-leveling mortar, the flow-regulating property of HPS can ensure the uniform spread of the slurry and reduce bleeding and segregation. Its water-retaining effect helps cement to fully hydrate, enhancing its strength and surface density, thereby improving overall durability and flatness.

2.4. Application in Gypsum-based Products

HPS can effectively control the setting time of gypsum, providing construction workers with more sufficient operating space. Its thickening and water-retaining effects reduce the risk of surface cracking in gypsum products, while enhancing the construction feel and surface fineness.

The mechanism by which HPS enhances construction performance

3.1. Molecular Adsorption and Hydration Regulation

The hydroxypropyl group in HPS molecules can form hydrogen bonds with water molecules, thereby locking the moisture in the system and maintaining the moist state of the material. This water-regulating effect makes the hydration reaction of cement or gypsum more complete, promoting the uniform development of strength.

3.2. Surface activity and Structural stabilization Effect

HPS can play a certain role in surface activity in the system, improve the dispersion of pigments and fillers, and prevent particle agglomeration. It can also form a stable three-dimensional network structure at the microscopic level, enhance the thixotropic recovery ability during construction, and enable the material to exhibit excellent smoothness and anti-sagging properties during the processes of scraping and spraying.

3.3. Synergistic Effect

When HPS is used in combination with HPMC and RDP (redispersible latex powder), a significant synergistic effect can be formed: HPS provides rheological regulation and water retention, HPMC enhances construction performance and opening time, and RDP offers flexibility and adhesion, thereby achieving a balance and improvement in the comprehensive performance of building materials.

Performance Optimization and Application Trends

In the future, construction-grade HPS will develop towards high substitution degree, high transparency and low viscosity loss. Through molecular structure optimization and etherification process improvement, its adaptability in high-strength mortar and self-leveling materials can be further enhanced. Meanwhile, with the improvement of building energy conservation and green environmental protection standards, the sustainable sources and low-carbon preparation processes of HPS will become important directions for industry research and development.

Building-grade HPS, with its unique molecular structure and multi-functional performance, plays an irreplaceable role in modern building materials. Whether it is enhancing the smoothness of construction, improving water retention performance, or strengthening the stability and durability of mortar, HPS has demonstrated significant advantages. With the continuous advancement of technology, its application fields will be further expanded, providing a solid boost for the sustained development of green and high-performance building materials.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland