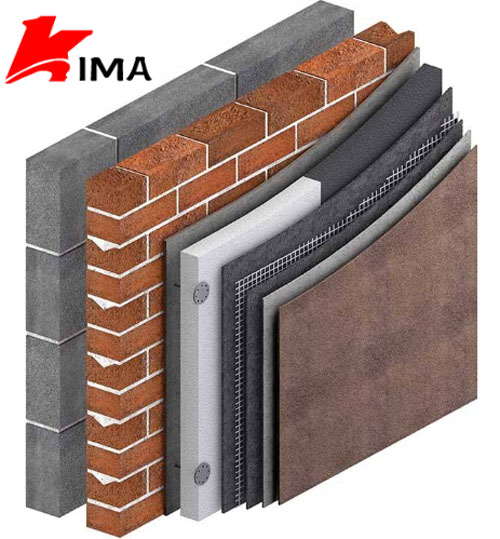

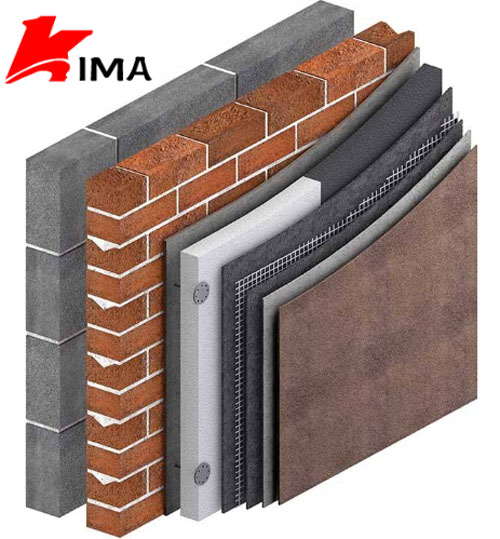

Exterior Insulation and Finish System (EIFS) is a technology widely used in the field of building energy conservation. It improves the thermal performance of buildings and reduces energy consumption by installing an insulation layer on the surface of the building's exterior walls. Hydroxypropyl Methyl Cellulose (HPMC) is a functional additive commonly used in EIFS systems. Its main functions include improving the workability of mortar, enhancing adhesion, and improving water retention.

1. The main function of HPMC in EIFS

HPMC is a water-soluble polymer compound. Its main role in the EIFS system is reflected in the following aspects:

1.1 Improving the water retention of mortar

The bonding mortar of the EIFS system is usually composed of cement, sand, filler and polymer. The proper retention of water is crucial to the performance of the mortar. HPMC has a strong water retention capacity, which can reduce the premature evaporation of water in the mortar and ensure that the cement hydration reaction is fully carried out. This not only improves the bonding strength of the mortar, but also reduces the risk of cracking.

1.2 Improved construction performance

HPMC gives EIFS mortar better construction properties, making it easier to apply and spread, and avoiding sticking or sagging. In addition, HPMC can make construction operations smoother, improve work efficiency and reduce labor intensity by improving the rheological properties of the mortar.

1.3 Enhanced adhesion and anti-slip properties

In the EIFS system, the mortar needs to have good adhesion to ensure that the insulation board (such as EPS, XPS or rock wool board) can be firmly adhered to the base wall. HPMC enhances adhesion by increasing the viscosity and wettability of the mortar, allowing it to better wrap the surface of the insulation board. In addition, it can prevent the insulation board from slipping due to gravity and improve the stability of construction.

1.4 Improved crack resistance

The EIFS system is susceptible to temperature changes and environmental stress, resulting in shrinkage cracks in the mortar layer. HPMC can effectively reduce the occurrence of cracks and improve the durability of the system by improving the flexibility and shrinkage resistance of mortar.

1.5 Optimizing anti-sagging performance

For facade construction, the sagging problem of mortar will affect the construction quality. HPMC can adjust the viscosity of mortar so that it can be quickly shaped after application, reduce sagging, and ensure uniform coating.

2. The impact of HPMC on different components of EIFS system

2.1 Impact on bonding mortar

HPMC can improve the bonding strength and workability of bonding mortar, enhance the adhesion of mortar to the base wall and insulation board, and reduce bonding failure caused by changes in the construction environment.

2.2 Impact on anti-crack mortar

Anti-crack mortar is usually located in the outermost layer of EIFS to protect the insulation layer and enhance weather resistance. HPMC plays a role in water retention, enhanced bonding and anti-cracking, and improves the flexibility and impact resistance of mortar.

2.3 Impact on the finishing layer

The finishing layer of EIFS is usually paint or decorative mortar. HPMC can improve its brushing performance, make the surface smoother, and improve weather resistance and water resistance, extending the service life.

3. Impact of HPMC dosage and selection on EIFS

3.1 Impact of HPMC dosage

A moderate amount of HPMC can improve the performance of mortar, improve workability and adhesion;

Excessive HPMC may cause the mortar to set longer, affect the construction progress, and reduce the mechanical strength of the mortar.

3.2 HPMC viscosity selection

Low viscosity HPMC is suitable for systems that require faster curing, such as thin-layer bonding mortar;

High viscosity HPMC is suitable for systems that require higher water retention, such as thick-layer anti-cracking mortar or mortar used in high temperature environments.

HPMC plays a key role in the EIFS system. It can improve the water retention, adhesion and workability of the mortar, and enhance the crack resistance and durability of the system. However, the use of HPMC should be reasonably selected and controlled according to specific needs to ensure the stability and long-term performance of the EIFS system. Reasonable use of HPMC can not only optimize the construction quality of EIFS, but also improve the energy-saving effect of the building and extend the service life of the system.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland