Hydroxypropyl starch ether (HPS) and hydroxypropyl methylcellulose (HPMC) are both modified polysaccharides widely used in industries such as pharmaceuticals, construction, food, and cosmetics. Though they share similar functional groups (e.g., hydroxypropyl), they differ fundamentally in their chemical origin, structure, physical properties, and industrial applications.

1. Chemical Origin and Structure

Hydroxypropyl starch ether (HPS):

HPS is derived from natural starches, such as corn, potato, or tapioca starch, which are polysaccharides made of α-D-glucose units linked mainly by α-1,4 glycosidic bonds with occasional α-1,6 branching. During hydroxypropylation, propylene oxide reacts with the hydroxyl groups in the starch molecules, introducing hydroxypropyl groups and altering its properties. The result is a nonionic, water-soluble or water-dispersible polymer with improved stability.

Hydroxypropyl Methylcellulose (HPMC):

HPMC is synthesized from cellulose, the primary structural component of plant cell walls, which consists of β-D-glucose units linked by β-1,4 glycosidic bonds. Through etherification reactions, cellulose is first treated with alkali and then reacted with methyl chloride and propylene oxide. This introduces both methoxy (-OCH₃) and hydroxypropyl (-CH₂CHOHCH₃) groups, resulting in a water-soluble, semi-synthetic polymer with thermogelation properties.

Key Differences:

Source: HPS is starch-based; HPMC is cellulose-based.

Bond types: Starch has α-linkages; cellulose has β-linkages.

Substitution groups: HPS contains only hydroxypropyl groups, while HPMC has both hydroxypropyl and methyl groups.

HPMC stands out for its thermogelation properties—it forms a reversible gel when heated, which is useful in many applications such as sustained drug release or as a thickener in food and personal care products. HPS does not exhibit this property.

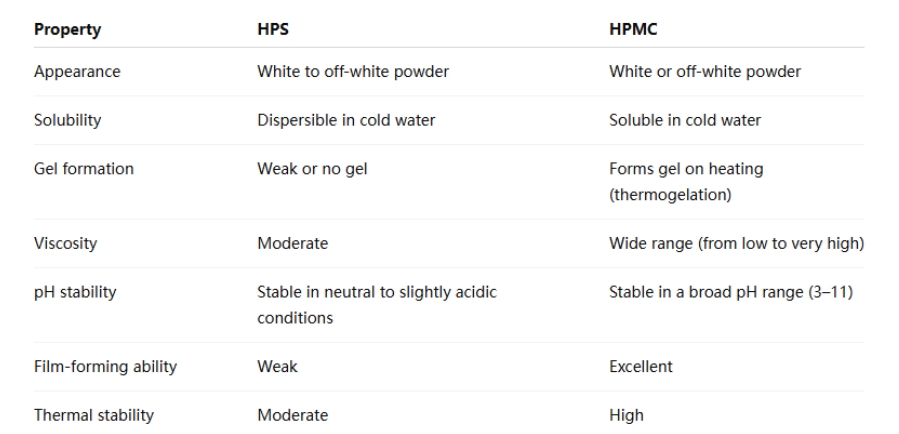

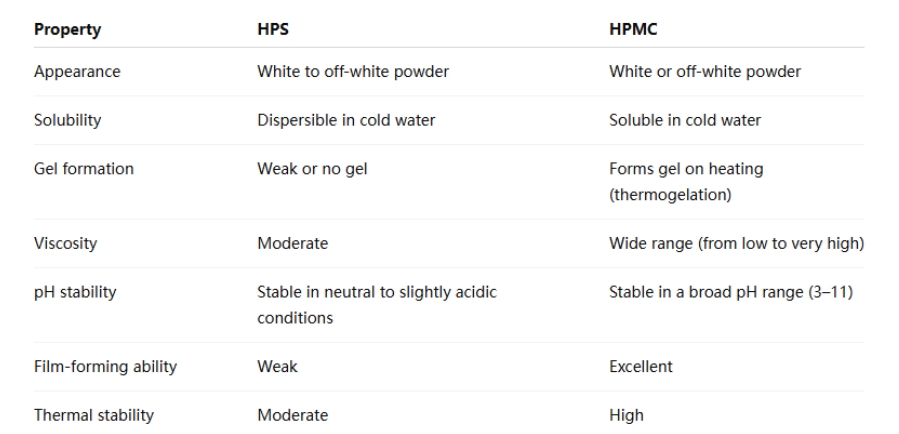

3. Functional Properties

Hydroxypropyl starch ether:

Thickening agent: Provides body and viscosity in aqueous systems.

Stabilizer: Prevents syneresis (liquid separation) in gels and suspensions.

Binder: Used in tablets and food systems to provide structural cohesion.

Low retrogradation: Modified starches like HPS reduce staling in baked goods.

Hydroxypropyl Methylcellulose:

Binder and film former: Critical in tablet coatings and granulation processes.

Thickener and emulsifier: Widely used in cosmetics, eye drops, and foods.

Controlled-release agent: Used in extended-release pharmaceutical formulations.

Thermogelation: Useful in 3D printing, food processing, and drug delivery.

4. Industrial Applications

Pharmaceutical Industry:

HPS: Used as a filler or disintegrant in tablets, though less commonly than cellulose derivatives. It may also be used in oral suspensions or modified-release formulations, but its application is limited due to its lower film-forming and binding capacity.

HPMC: Extensively used in pharmaceutical tablets as a binder, film-coating agent, and controlled-release matrix. Its safety profile and regulatory approval (USP, Ph. Eur.) make it a pharmaceutical industry standard.

Food Industry:

HPS: Used as a thickener, stabilizer, and moisture retainer in soups, sauces, dairy products, and baked goods. It helps improve freeze-thaw stability and texture in processed foods.

HPMC: Used as a vegetarian gelatin substitute, emulsifier, and stabilizer in products like gluten-free bread, dairy alternatives, and nutritional supplements.

Construction Industry:

HPS: Acts as a thickener and water retention aid in cement-based and gypsum-based mortars. However, its performance is generally considered inferior to HPMC.

HPMC: A critical additive in dry-mix mortars, tile adhesives, grouts, and skim coats. It improves workability, water retention, open time, and adhesion strength.

Cosmetics and Personal Care:

HPS: Less common, but may be used as a stabilizer or texturizer in lotions and creams.

HPMC: Used in shampoos, lotions, eye drops, and gels for its non-toxic, non-irritating, and stabilizing properties.

5. Biodegradability and Safety

Both HPS and HPMC are biodegradable and considered non-toxic, making them safe for use in food and pharmaceutical applications. However, regulatory approvals and industry usage heavily favor HPMC due to its established pharmacopoeial standards and safety data.

6. Rheological Behavior

HPMC demonstrates superior rheological properties, offering a wide range of viscosity grades, which makes it ideal for applications requiring precise control of flow and texture. In contrast, HPS has a more limited viscosity range and less predictable behavior under stress, especially in high-temperature or high-shear environments.

7. Cost and Availability

HPS: Generally less expensive and readily available due to its starch origin and simpler production process. Suitable for cost-sensitive applications, especially in the food and construction industries.

HPMC: More expensive due to complex synthesis and purification, but widely used where performance outweighs cost, particularly in pharmaceuticals and specialty formulations.

8. Regulatory and Environmental Considerations

HPMC complies with various international pharmacopoeias and food safety standards (e.g., FDA, EFSA, USP), making it widely accepted across regulated industries. HPS, while generally recognized as safe (GRAS), does not always have the same breadth of regulatory support, particularly in pharmaceutical formulations.

While Hydroxypropyl starch ether and hydroxypropyl methylcellulose share some structural similarities due to the presence of hydroxypropyl groups, they are fundamentally different in their sources, properties, and applications:

Hydroxypropyl starch ether is starch-based, inexpensive, and mainly used as a thickener or stabilizer in food and construction applications.

Hydroxypropyl methylcellulose is cellulose-based, multifunctional, and widely used in pharmaceuticals, food, and personal care due to its film-forming, gelling, and controlled-release capabilities.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland