Hydroxyethyl Cellulose (HEC) is a non-ionic water-soluble polymer derivative made from natural cellulose through chemical modification. It is widely used in many industrial fields, especially in coatings, building materials, oil extraction, daily chemical products and pharmaceuticals. HEC has excellent performance characteristics,

1. Stable physical and chemical properties

HEC is a white or slightly yellow, odorless, tasteless powder or granular solid with good chemical stability. The hydroxyethyl group in its molecular structure gives it excellent water solubility and thermal stability, and it is not easily affected by conventional acids and alkalis, so it remains stable in a wide pH range (generally 2~12). Its non-ionic properties make it difficult to react with charged ions, avoiding performance changes caused by ionic reactions.

2. Good solubility

HEC can dissolve in cold and hot water to form a clear and stable colloidal solution. It does not agglomerate when dissolved in water, forming a uniformly dispersed solution. This feature makes it easy to use in the production process. In addition, HEC has a high dissolution rate, especially after surface treatment, its initial dispersibility is better, avoiding agglomeration, which helps to improve construction efficiency.

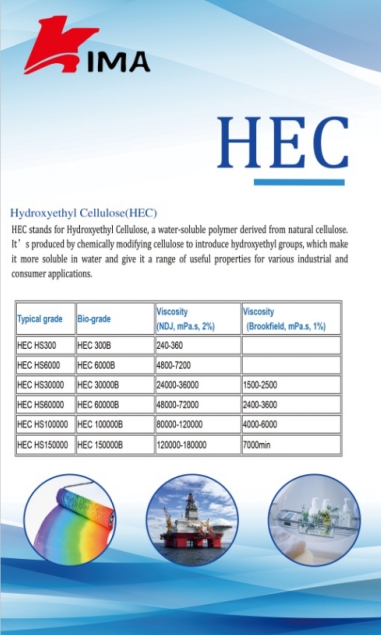

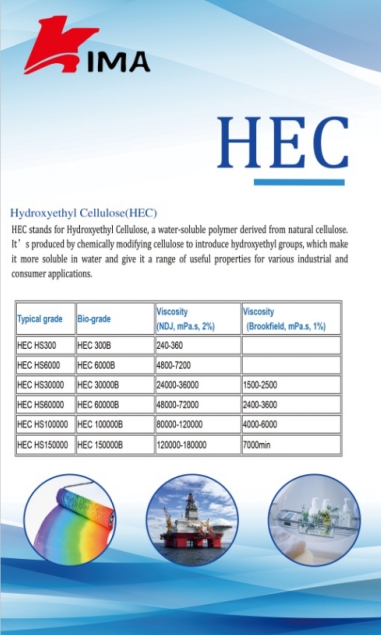

3. Excellent thickening effect

HEC, as an effective thickener, can provide significant viscosity at low concentrations and has good rheological control ability. Its thickening effect is stable and is not significantly affected by factors such as temperature, salts, and electrolytes. HEC can effectively control the fluidity of the system, improve the workability and spreadability of the product, especially in coatings, oilfield fracturing fluids and daily chemical products.

4. Good rheological behavior

The rheological properties of HEC solution can be expressed as pseudoplasticity, that is, as the shear rate increases, the viscosity of the solution decreases. Such rheological properties help to improve the brushing, rolling and spraying performance during the construction process, and facilitate operation. Pseudoplasticity can also effectively prevent the coating from sagging when it is stationary and improve the film uniformity of the product. In addition, in oil drilling fluids and fracturing fluids, HEC can adjust the rheological properties of the liquid and improve drilling efficiency.

5. Good film-forming property and adhesion

HEC has good film-forming property, and has certain flexibility and strength after film formation. In the coating industry, it can enhance the adhesion of the paint film and improve the scrub resistance and wear resistance of the coating. After film formation, it has good adhesion to the substrate and moderate air permeability, which will not cause the base layer to "suffocate", which is extremely important in the field of construction and decoration.

6. Strong suspension and emulsification stability

Due to its high surface activity, HEC can significantly improve the suspension performance of solid particles in the solution, prevent sedimentation, and keep the product uniform during storage. In addition, HEC can also improve the emulsification stability in the emulsion system and prevent oil-water separation, thereby improving the appearance stability and service life of the product.

7. Good compatibility and compatibility

As a non-ionic polymer, HEC has good compatibility with a variety of active components, and can be well compatible with cationic, anionic or non-ionic surfactants, polymers, etc., and is not easy to precipitate or react. This feature makes HEC highly flexible in formula design.

8. Environmental friendliness and biodegradability

HEC is derived from natural cellulose, has good biocompatibility and low toxicity, and is widely used in medicine and daily chemical products, such as toothpaste, shampoo, skin care products, etc. It can be gradually degraded by microorganisms in the environment, has little impact on the ecological environment, and is in line with the current development trend of green environmental protection.

9. Wide application fields

Thanks to its excellent properties, HEC is widely used in:

Coating industry: as a thickener, dispersant and film-forming aid, improve construction performance, anti-sagging and storage stability.

Building materials industry: used in cement mortar, putty powder, etc., to improve construction smoothness, water retention and anti-sagging.

Oil extraction: provides good thickening, suspension and lubrication in drilling fluid and fracturing fluid.

Daily chemical products: used as thickener and foam stabilizer in shampoo, shower gel, etc. to improve product texture.

Pharmaceutical industry: used as tablet binder, emulsion stabilizer or sustained-release material.

As a water-soluble polymer material with excellent performance, hydroxyethyl cellulose HEC has great application value in many industrial and civil fields due to its good thickening, strong solubility, good rheology, high compatibility, environmental protection and non-toxicity. With the continuous advancement of green chemistry and sustainable development concepts, HEC will have a broader market prospect in the future, and its performance will continue to be optimized and expanded to serve more new materials and high-end application fields.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland