In modern building materials systems, hydroxypropyl methylcellulose (HPMC) is an almost indispensable additive in various dry-mix mortars. From tile adhesives and putty powders to plastering mortars and self-leveling materials, HPMC is widely used. This is not accidental, but due to the core role HPMC plays in improving mortar workability, enhancing material stability, and optimizing final mechanical properties. Its unique chemical structure gives it significant multifunctionality in cement, gypsum, and other inorganic cementing material systems, making it the most widely used cellulose ether variety in the industry.

HPMC improves mortar water retention, reducing rapid water loss.

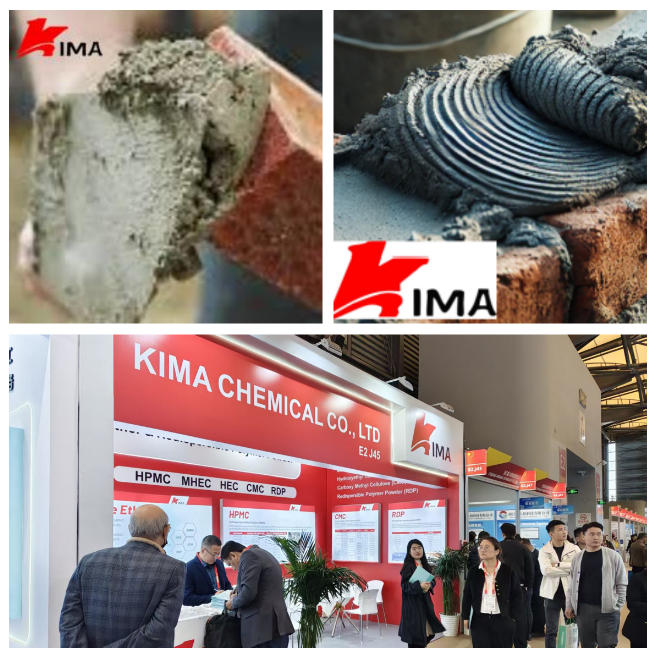

If mortar loses water too quickly during construction, it can lead to insufficient hydration of the cementing material, resulting in problems such as insufficient strength, cracking, and delamination. HPMC has excellent water retention capabilities, forming a continuous polymer network structure within the mortar system, locking water inside the system and ensuring that cement and hydrated lime undergo hydration reactions under suitable humidity.

Especially under high temperature, strong wind, and absorbent substrate conditions, the water retention effect of HPMC is even more crucial, which is one of the main reasons why it is an essential additive in tile adhesives and plastering mortars.

Significantly improves mortar workability and consistency.

The thickening effect of HPMC allows the mortar to achieve appropriate consistency and thixotropy, making it low viscosity during mixing, easy to spread during application, and able to regain viscosity after standing, improving the mortar's anti-sagging performance.

In putty or thin-layer plastering, the addition of HPMC can make the scraping feel smoother and reduce sagging; in tile adhesive systems, it helps improve wet adhesion, preventing the mortar from slipping on vertical surfaces during application and ensuring the uniformity of the adhesive layer.

Enhances mortar bonding strength.

Although HPMC itself is not an adhesive, its water retention and film-forming properties can indirectly improve the bonding effect between the mortar and the substrate and sand particles. By delaying the cement hydration time and maintaining interfacial moisture, HPMC allows the gel substance to have enough time to penetrate the capillary pores of the substrate, increasing mechanical interlocking force. Furthermore, HPMC forms a flexible organic film in mortar, compensating for the brittleness of inorganic cementing systems, enhancing the bonding stability of the material, and reducing the risk of delamination and hollowing.

Improving the anti-slip, anti-sagging, and film-forming properties of mortar

For systems requiring anti-slip properties, such as tile adhesives, the thixotropic properties of HPMC are crucial. HPMC with the appropriate viscosity grade and degree of substitution allows the mortar to be applied without slipping, sagging, or edge collapse.

In putty powder, the uniform film-forming effect of HPMC improves the surface density and flatness of the material, resulting in more even sanding and preventing powdering and peeling after film formation.

Enhancing the stability and shelf life of mortar

In dry-mix mortar, HPMC has excellent anti-segregation and anti-stratification properties, maintaining the uniform distribution of cementing materials, aggregates, and various additives. Its thickening structure helps improve the wet-state stability of the mortar, preventing water separation and material segregation. This makes pre-mixed mortar more stable during storage, mixing, transportation, and construction.

Strong adaptability: Suitable for cement, gypsum, and various mixed systems

HPMC has good compatibility and is suitable for:

Cement-based mortars

Gypsum-based materials

Lime-based mortars

Polymer-modified mortars (such as tile adhesives, EIFS, leveling layers, etc.)

Whether low-viscosity, fast-dissolving types or high-viscosity, water-retention enhancing types, HPMC can meet different application scenarios through specification selection.

The reason why HPMC is widely needed in mortar is that it provides comprehensive performance improvements in terms of water retention, thickening, workability, bonding strength, and stability. HPMC has become an indispensable key additive in modern dry-mix mortar systems. Its addition not only improves the construction experience but also ensures the long-term durability and quality of the project. For any pre-mixed mortar company or construction unit, the rational selection and use of HPMC is an important way to enhance product competitiveness.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland